It started quite well in the cold and the snow blower blades were spinning, ready for work.

But then I could not move the tractor out of the garage, it did not move an inch, not forth nor reverse (the rear axle was in low gear :wink .

.

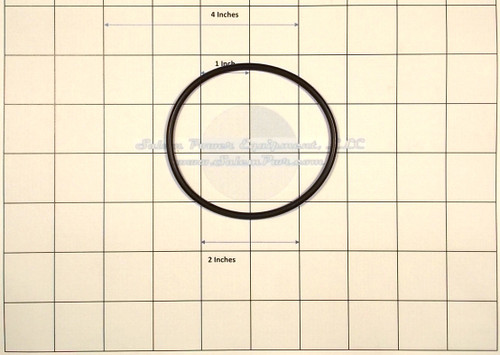

I looked down to left rear axle- the small red pumpkin (hydraulic motor) ...I saw oil coming out from the outer cover.

What is going on?

Is the motor repairable? And if yes. How can I get the repair kit?

If not repairable... what are the options?

Thanks so much, Martin

But then I could not move the tractor out of the garage, it did not move an inch, not forth nor reverse (the rear axle was in low gear :wink

I looked down to left rear axle- the small red pumpkin (hydraulic motor) ...I saw oil coming out from the outer cover.

What is going on?

Is the motor repairable? And if yes. How can I get the repair kit?

If not repairable... what are the options?

Thanks so much, Martin